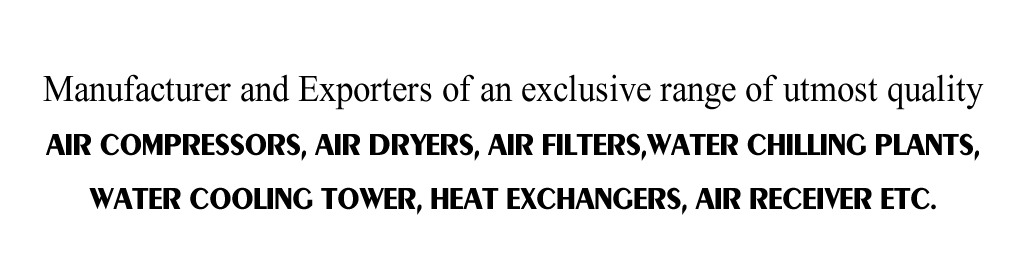

Ingersoll Rand Type 30 Series high pressure air

compressors feature base-mounted piston technology that provides pressure as

high as 5,000 psig (345 barg). Typical applications include refueling

stations, PBM, power plants and engine starting. Using the same durable

construction found in all of our two-stage reciprocating compressors, the

high pressure units offer reliability, long life and easy maintenance.

- Long-Life: Durable cast iron frame and cylinder, heavy-duty steel

base construction, NEMA-rated enclosure for engine

- Superior Pump Efficiency: Separately cast cylinders with deep radial

fins for improved cooling and efficiency

- Smooth Starting: Auto start/stop regulation by pressure switch;

centrifugal unloader ensures loadless starts for maximum protection

- Advanced Safety Features: Standard low oil-level switch to provide

constant protection of the compressor

- Reliable Operation: All Season Select synthetic lubricant increases

efficiency; with 2,000 hours of service between changeouts, it performs

four times longer than petroleum-based lubricants

- Two-Year Warranty Available: Purchase an All-Season Select lubricant

start-up kit, and receive all the parts you need for start-up and the

first year of maintenance, along with an extended pump warranty